Addressing the issue of LED bulbs easily falling off during the installation or dis mental of traditional small-pitch LED screens, GLOSHINE, leveraging its profound experience and forward-looking vision in the LED display field, has reinvented the wheel by integrating multiple key technologies in material sourcing, R&D design, and production processes. Through innovative research and development, Gloshine has introduced the S-SMT technology, breaking through the technical limitations of conventional rental screens and enhancing the stability and durability of displays. This marks a revolutionary technological transformation for the LED display industry.

SMT process is fully upgraded: pinless encapsulation improves LED performance

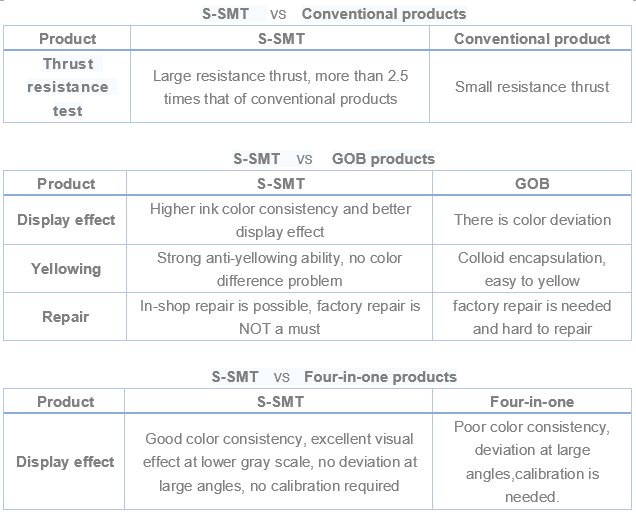

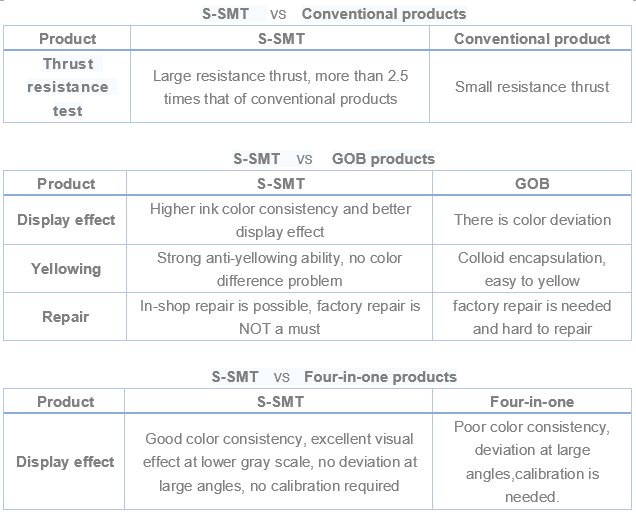

Gloshine integrates upstream and downstream supply chain resources and takes the lead in adopting the latest lamp bead products in the industry. Its pinless design optimizes the internal structure of the lamp bead, and the contact area between the pin and the pad is increased by 70%. This increases the thrust resistance of the LED display to more than 2.5 times that of conventional products, significantly reducing the failure rate and maintenance costs. It also effectively improves the SMT positive and negative surfaces and heat dissipation issues, ensures good color consistency, provides LED display with a wider viewing angle and higher brightness contrast, and brings a more shocking visual experience to the audience.

S-SMT LED lamp bead VS Conventional lamp bead

Optimize PCB pad size: high-quality welding, multiple thrust resistance guarantees

The PCB pad design is combined with a unique process of steel mesh window opening to ensure that the pad size reaches extremely high precision, achieve precise matching between the lamp bead and the PCB pad, and improve the reliability and stability of welding.

.png)

Reflow soldering

More precise dispensing process: accurate filling and less interference

By adjusting the matching degree of solder paste and glue, and introducing a high-precision dispensing valve system and precise dispensing technology, the bonding strength between the lamp beads and the PCB is greatly enhanced, making the overall structure more solid and effectively reducing the risk of damage to the lamp beads by external forces. At the same time, it also eliminates the visual granularity problem caused by uneven light distribution in conventional products, bringing users a more delicate and uniform visual experience.

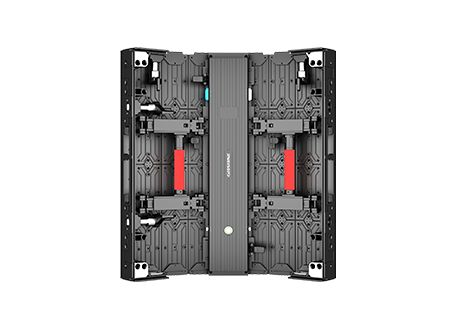

Indoor module automated production line

The above series of measures have jointly built a solid foundation for S-SMT technology, providing the market with more durable and reliable LED display solutions.

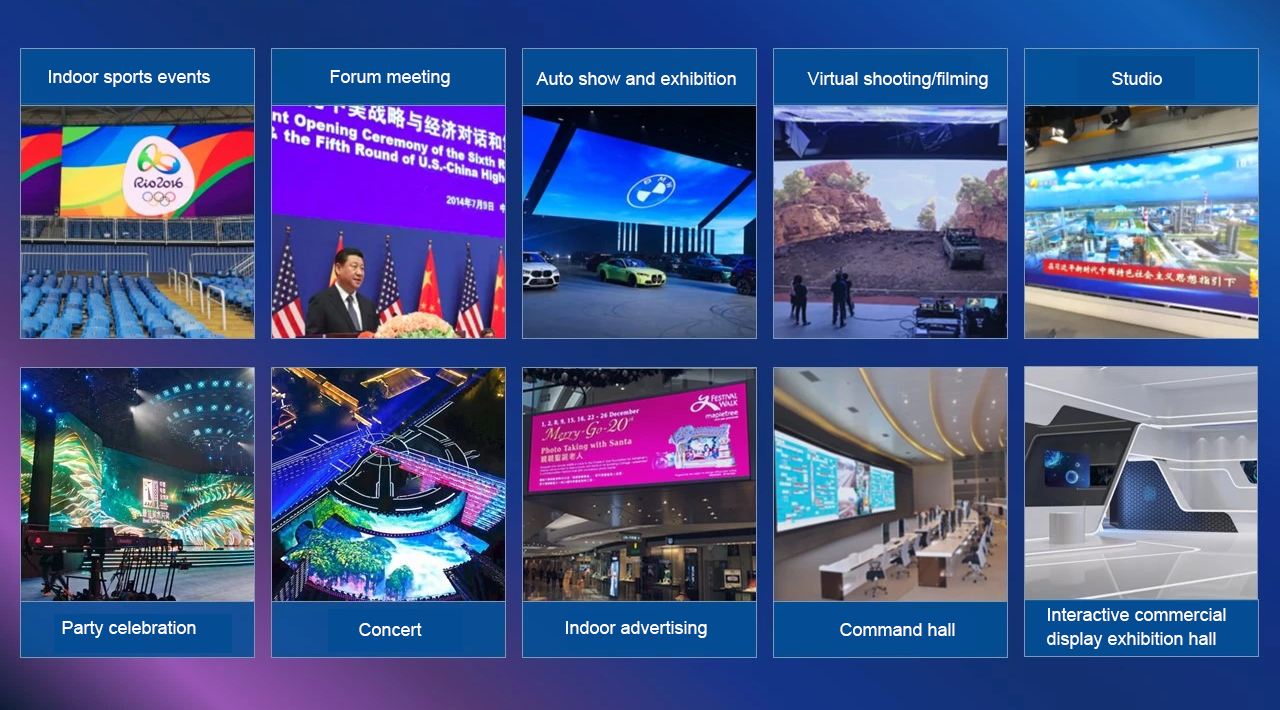

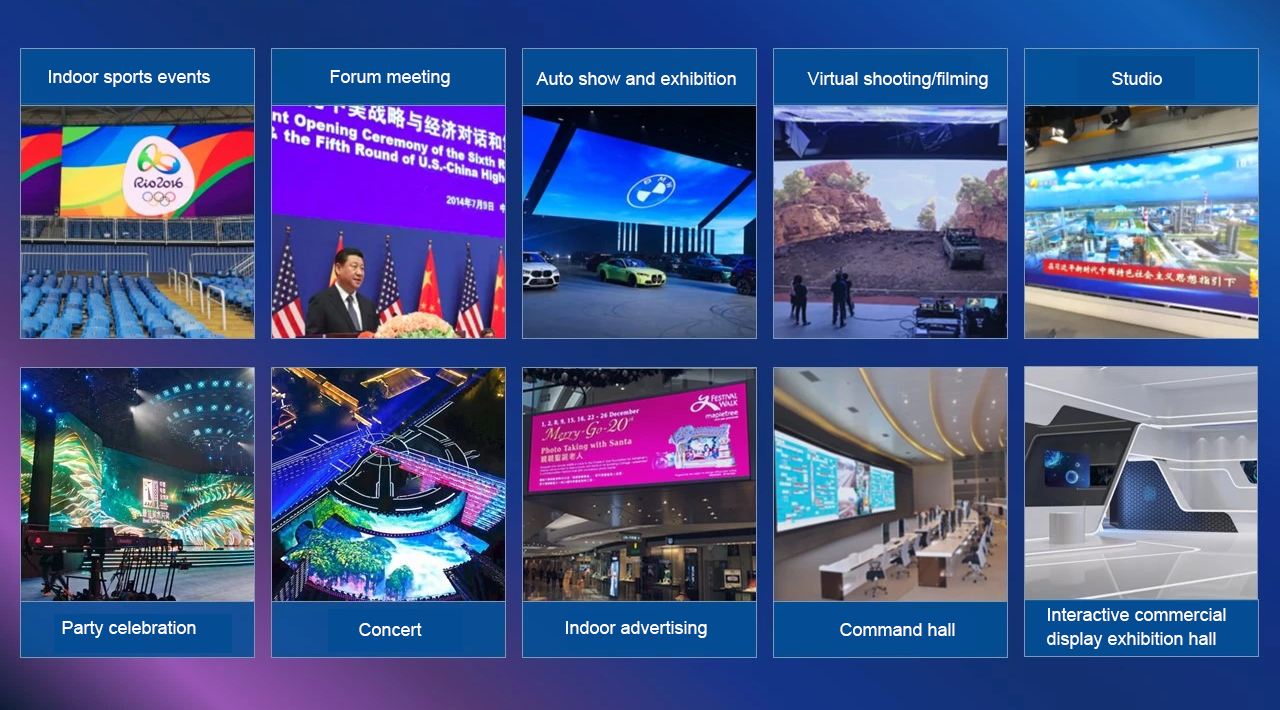

In the coming days, S-SMT technology will be gradually applied to Gloshine's various product series to further enhance the stability and durability of the products, effectively extend the service life of the screen, reduce the cost of long-term use, and improve the smoothness and color expression of the display image, bringing customers better indoor rental solutions and opening up a new visual experience for multi-scenario applications.

Conclusion

In the future, Gloshine will continue to increase its investment in research and development, keep moving forward on the road of technological innovation and product upgrades, and use the power of technology to create the beauty of the visual world.

cn

cn en

en es

es ru

ru pt

pt

.png)